As prototype CNC machining has become popular and important in the manufacturing industry, it is necessary for us to know more about it. This article is from Wayken rapid manufacturing, visit their website and maybe can help you to understand them more.

What is CNC prototyping?

Source: vokmodel.com

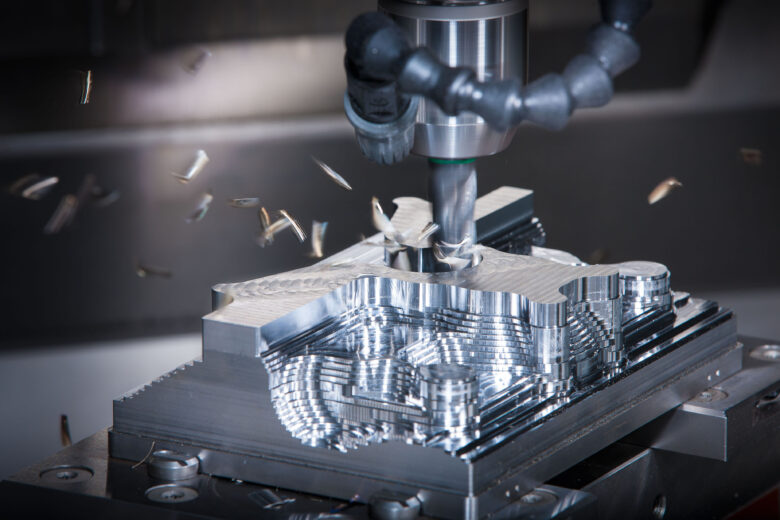

In this fast growing modern manufacturing industry, the fabrication of a product prototype has become very convenient. Nowadays, a product prototype can be fabricated by employing an automatic manufacturing process of 3-D models rendered directly from a design software (CAD). This process is commonly known as Rapid Prototyping (RP). Modern rapid prototyping practices can automatically construct physical models without any human intervention, i.e. 3D printing. However, each of the processes are restricted to a limited variety of materials or minimal geometric accuracy. Thus, the emergence of a new approach is established by merging the important features of CNC machining and the prevailing rapid prototyping technologies.

The CNC rapid prototyping process is able to overcome the previous limitations of RP process. These contemporary CNC machines are adept to function at high precision, high speed, and high flexibility. Subsequently, a new hybrid manufacturing system can be implemented by the operative blend of RP and CNC machineries that is entirely able to meet the next generation production systems requirements. It is particularly very useful for the short-run production systems. The following figure replicates the conjunction between RP that is suitable for rapid manufacturing and high precision final product.

Advantages of CNC prototyping

Source: uidearp.com

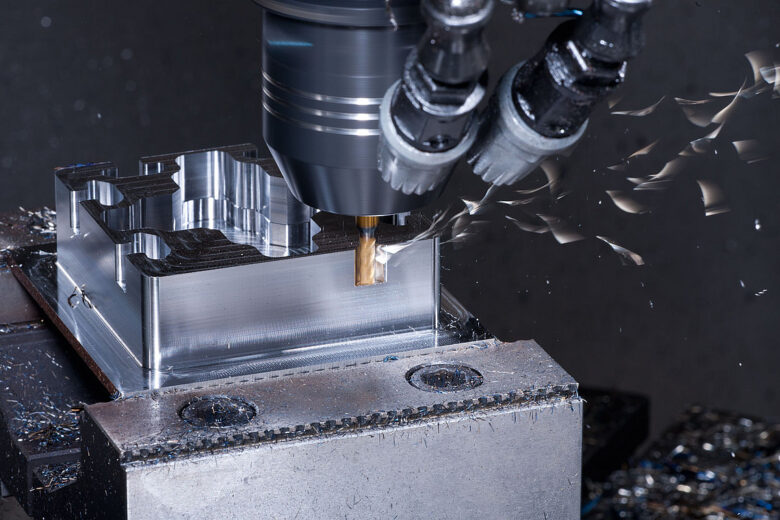

People who are planning to manufacture custom designed high precision metal or plastic parts, depends largely on CNC prototyping. What could be the possible reasons behind their motive of thinking? The answer is fairly easy because CNC prototyping is way ahead of its competitors in terms of fabricating products within a short period of time, with less manpower or human intervention, high precision and what not! Let’s have a look what are some of the major advantages of CNC machining.

|

Precision

|

|

Reliability

|

|

Scalability and High Production

|

|

Material Friendly

|

|

Versatility

|

|

Enhanced Safety

|

CNC prototyping Services

Source: youtube.com

There are a variety of CNC prototyping techniques available based on movement that is either linear, or a straight line, in motion or rotational. For linear movements, generally the X, Y and Z axis are used. On the other hand, A, B or C resemble to rotational axis. The most common types of machining techniques are briefly introduced here.

- CNC milling

Milling machines are the most commonly used variety of CNC machine. It is much similar to both cutting and drilling. Rotary cutters are used to remove excess material from a part when it is inserted into the milling tool. For the wide variety of detailed shapes and sizes milling can accommodate, it is a popular industrial solution.

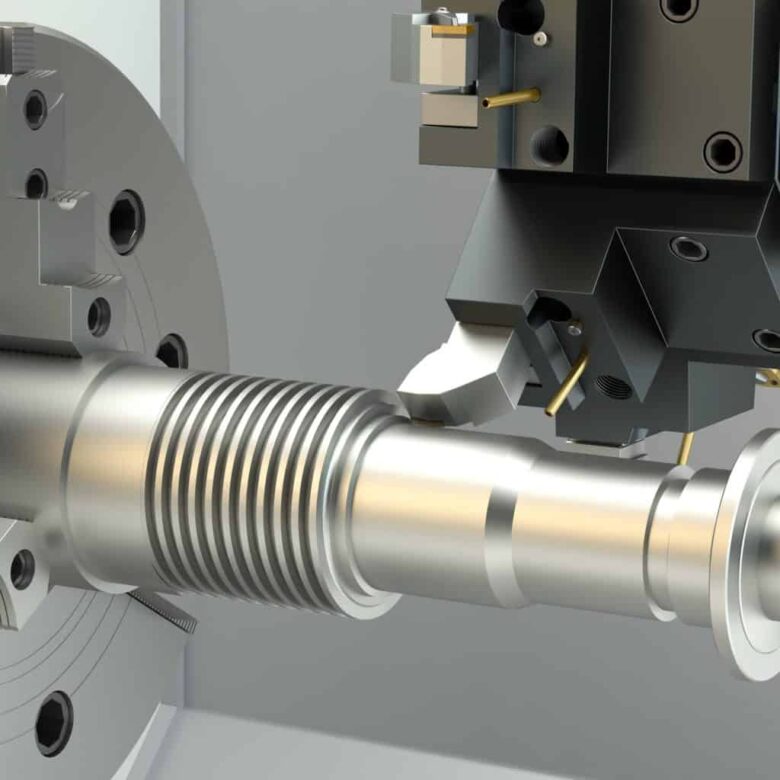

- CNC turning

Turning is a bit different from the milling process. It is a subtractive machining practice and a cutting tool is positioned beside a spinning piece to remove excess material. The most common machines to perform this operation are CNC lathe or turning center. It is applicable for a wide range of materials involving plastic, wood and metal.

The function of EDM is to remove materials precisely from a conductive material by using an electrode. It is like pushing a form into soft material, the electrode marks a negative imprint in the workpiece. It is also known as spark eroding, wire burning or wire erosion.

CNC Machining Applications

Source: geomiq.com

| Design & Rapid Prototyping | One of the most important applications: it is very easy to digitally prepare a design, input in the machine and get a prototype within a very short period of time. It involves less manpower, low-cost, less time and products with complex geometry. |

| Mold Making | The most common method to manufacture metal injection molds is to use CNC machining and EDM process. Apart from injection molds, it can be applied in fabricating molds for blow molding, high pressure die casting, roller molding, blending and so on. |

| Aerospace | Aerospace industry is one of the biggest customers of CNC prototyping owing to their requirement of high precision and delicate safety-critical parts to be used in the aircraft. |

| Automotive | Starting from miniature parts used in a vehicle up to the prototype of a fancy sports car can be easily manufactured using this method or rapid prototyping, which has been widely used to manufacture high volume of automotive parts. |

| Medical | Often used in healthcare to fabricate medical and biomedical devices made of stainless steel, titanium or plastic. Furthermore, the microfluidic devices benefits from the technique is growing rapidly. |

| Consumer products | At this moment, the consumer product market is dominated by injection molding process because of its high volume production, however, a lot of off-the-shelf goods are manufactured by the CNC machining process. Many household items and appliances along with sports equipment can be machined easily. You can also see its shadow in the electronic industry is also very widespread for its suitability to metal and plastic components; for example: laptop casings, sockets and connectors etc. |