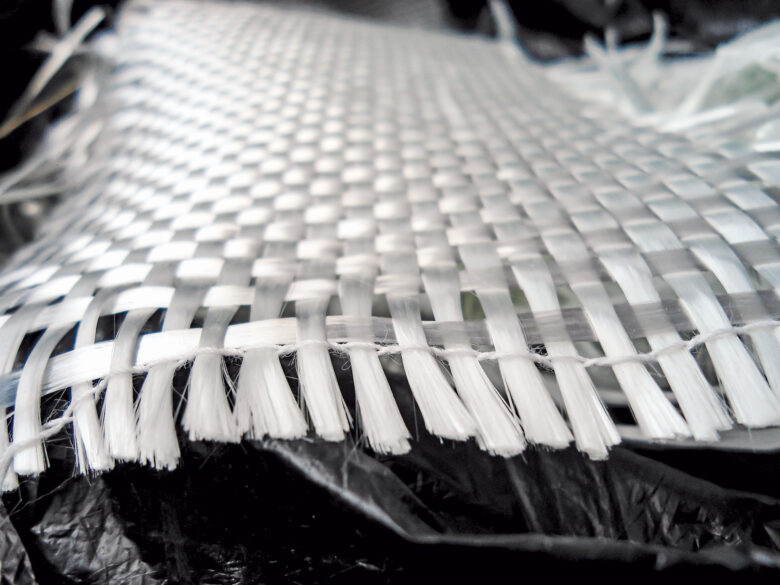

Fibreglass is the name given to a silicate fibre that is primarily made up of glass and made use of in a large array of applications, including for the purposes of thermal insulation in both residential and commercial properties. It is used to make the likes of tent poles, roofing, boat hulls, automobile bodies, shower curtains, arrows and electrical enclosures.

What are they?

Source: cen.acs.org

A fibreglass enclosure, like those that can be found at RS Components, is used to protect electrics from chemicals and other corrosive applications. They can be moulded under heat and pressure and then reinforced via a polyester resin, making them able to withstand dangerous properties including chemicals and extreme temperatures.

Why choose fibreglass enclosures instead of polycarbonate enclosures?

Fibreglass enclosures have been shown to be a much better choice than polycarbonate enclosures. They should always be used in situations that deal with organic solvents or in situations that operate in direct sunlight, neither of which polycarbonate equipment are well suited to dealing with.

They also come with superb electrical properties, can be consistently corrosive or wet environments, can cope with extreme temperatures ranging from -40 degrees Centigrade to 121C, and are also able to withstand impacts caused by exterior sources.

This type of enclosure is also a lot less expensive to install or have replaced.

There are other reasons why so many businesses are opting to make use of these enclosures ahead of other products. Fibreglass is stronger than sheet metal, can be safely installed in environments that come with high salt content, are safe near corrosive materials and is highly resistant to rust.

When you should use them

Source: mekco.com

When your engineers need a greater number of possibilities, fibreglass is the ideal choice because it is almost completely unrestricted in regards to moulding. This type of material can be used to make products that are not only strong and durable but also visually appealing in circumstances when aesthetic appearances may be important. Almost any feel or appearance can be created with a this enclosure or cover, which makes the finished product look very high tech and sophisticated.

Budget

These kinds of enclosures are also a good option when businesses are concerned about the budget. They are very low in price, especially in comparison to the notoriously fluctuating price of steel, but also comes with lower costs for maintenance and warranty work. When shipped or stored, it is also less expensive to ship because of its lightweight nature and its strength makes it able to take a few knocks along the way.

Non-conductive and absorbs sound

Source: vpcfiberglass.com

When a business wants to house electronics without having their performance disrupted or endangering employees with hazardous materials that may be contained within the housing, fibreglass is a great option due to the fact that it is non-conductive and radio frequency transparent.

When sound levels need to be met or business wishes to lower the sound of machines, the amazing acoustics of this material, which is able to actually absorb sound waves, make it the obvious choice.

Fibreglass is moisture resistant

When exposed to moisture, it will neither absorb nor hold that water. In the event that there is exposure to moisture during or after insulation, the this insulation will be inspected on all sides by the installers in order to check to make sure that it has not been contaminated. So long as there is none, the fibreglass insulation will then be completely dried until it has reached its complete R-Value.

Once all surrounding areas have also been cleaned, dried and inspected, the material will be fully restored and will have regained its entire value.

Made from recycled materials

Source: mfiberglass.com

Keeping our planet clean is something that the fibreglass manufacturing industry has become famous all over the world. In the 18 year period from 1992 to the year 2000, more than eight billion pounds worth of pre and post-consumer glass containers was recycled by the industry, with the amazingly high recycled content figure also meaning that millions of feet of landfill have been eliminated.

80% of the glass used in fibreglass insulation products like batt insulation, loose-fill and roll has been recycled. This kind of insulation also includes ingredients such as the likes of silica sand, a naturally renewing source. The impact that silica sand in the manufacturing process has on the environment is also minimal.

Fibreglass can be used in many applications

One of the main reasons why fibreglass enclosures are chosen for use in operations is their sheer versatility. These types of enclosures can be used in a large array of different applications, which is not always the case with other kinds of enclosures and shelters.

They can be used to protect everything from chlorination buildings to wastewater sampling stations and emergency safety showers, and are suitable for almost all storage requirements.

Fibreglass enclosures can be installed quickly

Source: signature-enclosures.com

Time is valuable in any kind of business, which means that the installation of an enclosure is something that needs to be accomplished as quickly as possible to minimise any disruption to company operations.

Fibreglass enclosures require surprisingly little installation time due to the fact that they come pre-fabricated. This means that there is no construction time to factor in and that the installation necessitates only that the enclosure is secured to a pre-made slab, thus saving businesses a great deal of hassle and time. When equipment needs protecting as soon as possible, this enclosure is by far the best way to get that protection installed quickly and easily.

Fibreglass enclosures can be used with solvents

Fibreglass can also easily handle exposure to solvents such as carbon tetrachloride, cleaning solvents and toluene as well as mild acids like boric acid, seawater and aluminium chloride. Industry professionals are choosing these enclosures over other types precisely because of these resistances.

Fibreglass enclosures are ideal for almost any business needs, and their employment means that companies will have the benefit of a reliable shelter ideal for equipment protection, safety and storage.